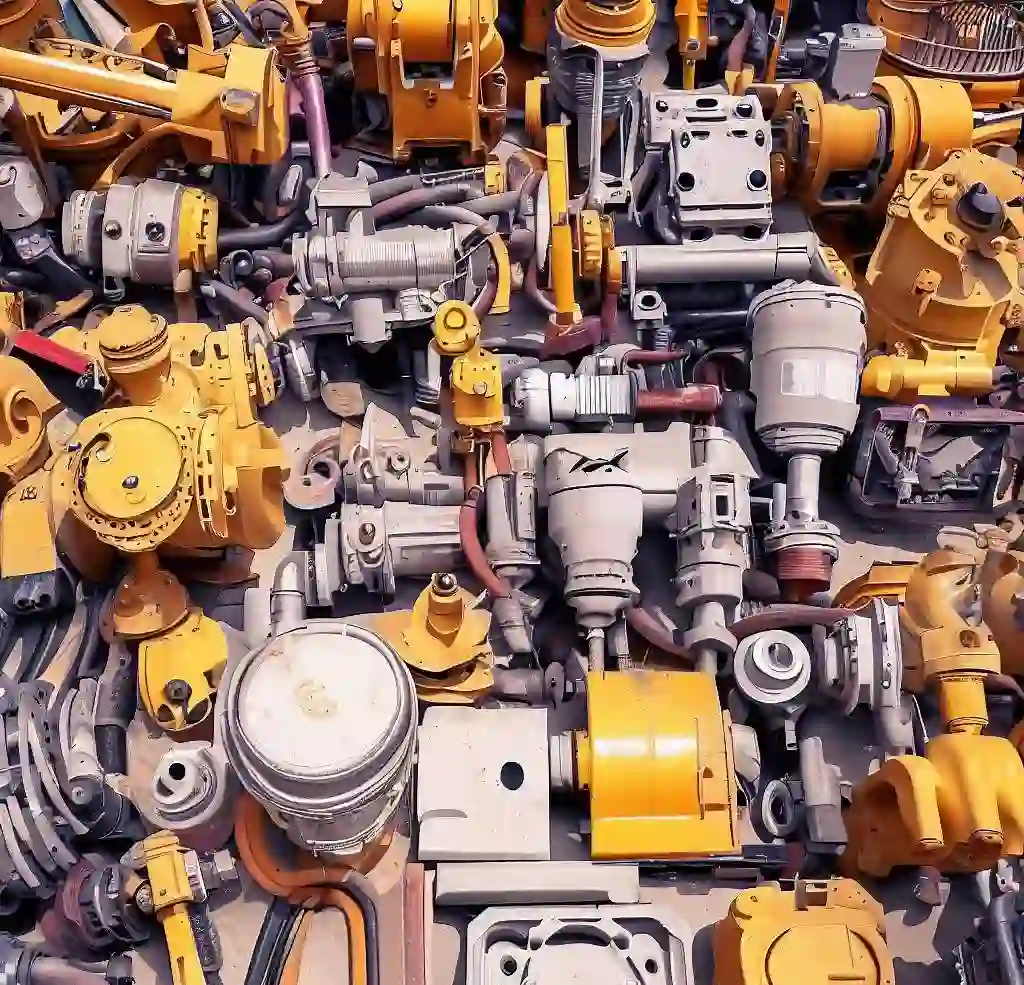

Concrete pumps are crucial equipment in the construction enterprise, facilitating the green delivery and site of concrete. Like any mechanical machine, concrete pumps require normal upkeep and occasional replacement of elements to make certain best performance. When faced with worn or malfunctioning additives, the choice to update concrete pump elements will become vital. In this weblog, we are able to discover the elements that decide whether or not replacing concrete pump components is a superb preference and the advantages it is able to deliver to production initiatives.

1. Cost-Effectiveness:

One of the key concerns when figuring out to replace concrete pump components is the fee-effectiveness. In many cases, replacing a specific element can be extensively extra low-cost than investing in an entirely new pump. By replacing worn or damaged parts, you may expand the lifespan of your concrete pump and avoid the rate of purchasing a new one. Additionally, replacement elements are frequently with ease available, lowering downtime and growing average productivity.

2. Performance Improvement:

Replacing worn-out or malfunctioning concrete pump elements can substantially improve the performance of the device. Over time, elements such as put on plates, pistons, seals, and hoses can revel in wear and tear, affecting the efficiency and effectiveness of the pump. By changing these components, you could restore the pump's functionality, making sure smoother concrete float, reduced downtime, and stepped forward universal productivity on the development web site.

3. Compatibility and Fit:

When opting to replace concrete pump elements, it's miles essential to make sure compatibility and match with your particular pump model. Reputable manufacturers and suppliers offer replacement elements designed to satisfy the specifications of various pump models. By deciding on notable, like minded parts, you may maintain the integrity of your pump's performance, as well as make certain the longevity of the alternative additives.

4. Time Savings:

The availability of alternative parts allows for quicker maintenance and reduced downtime. Instead of looking ahead to a brand new pump to be introduced or repaired, changing a defective element can be a greater time-efficient solution. This is particularly critical in construction projects with tight schedules and closing dates. By promptly replacing the vital parts, you may limit venture delays and hold operations going for walks easily.

5. Expertise and Support:

Replacing concrete pump elements often involves the help of informed specialists or technicians. Working with authentic providers or manufacturers ensures get entry to to knowledge and help at some stage in the alternative process. These professionals can provide guidance on choosing the right elements, provide recommendations for maintenance practices, and ensure that the substitute is performed correctly. Their understanding can assist optimize the overall performance of your concrete pump and offer treasured insights into preventive preservation to increase the lifestyles of the system.

6. Sustainability and Environmental Impact:

Choosing to update concrete pump elements aligns with sustainability efforts by way of reducing waste. Rather than casting off a whole pump, changing worn or broken parts allows for the reuse and recycling of different functioning additives. This contributes to a greater environmentally friendly approach inside the production industry, lowering the demand for new system and minimizing the carbon footprint related to production and transportation.

Replacing concrete pump components is a viable and beneficial preference for retaining and optimizing the performance of this important creation gear. It offers price-effectiveness, overall performance development, time savings, get entry to understanding, and sustainability blessings. By assessing the condition of your concrete pump, operating with reliable suppliers, and ensuring compatibility, you may make informed decisions on changing worn or malfunctioning elements. Embracing the exercise of replacing concrete pump elements whilst wished is a prudent strategy to ensure the reliability, performance, and sturdiness of your system, in the end contributing to a hit production projects.